Dubrovnik-During the operation of a large magnetic deburring machine, metal workpieces do not collide with each other, and after magnetic grinding, the product does not deform, does not affect accuracy, and does not damage the surface of the workpiece; Magnetic polishing equipment has strong stability and high efficiency in operation;

The large magnetic deburring machine has a fast working speed, with an average grinding time of about 3 minutes to 15 minutes. It has a fast replacement efficiency and can replace workpieces during the operation of the magnetic polishing machine;

The waterproof and moisture-proof design of the body of a large magnetic deburring machine ensures simple and safe operation without technical requirements, and can be operated by one person or multiple machines;

Large magnetic deburring machines can remove burrs from metal workpieces; Polishing the surface of the product; For example, hardware jewelry crafts; Precision hardware parts; Spring and shrapnel parts; Electronic, communication, and medical device parts; Centerless, cutting, CNC automatic lathe parts; Aerospace and other components; Suitable for metal workpieces such as gold, silver, copper, aluminum, zinc, magnesium, iron, stainless steel, etc.

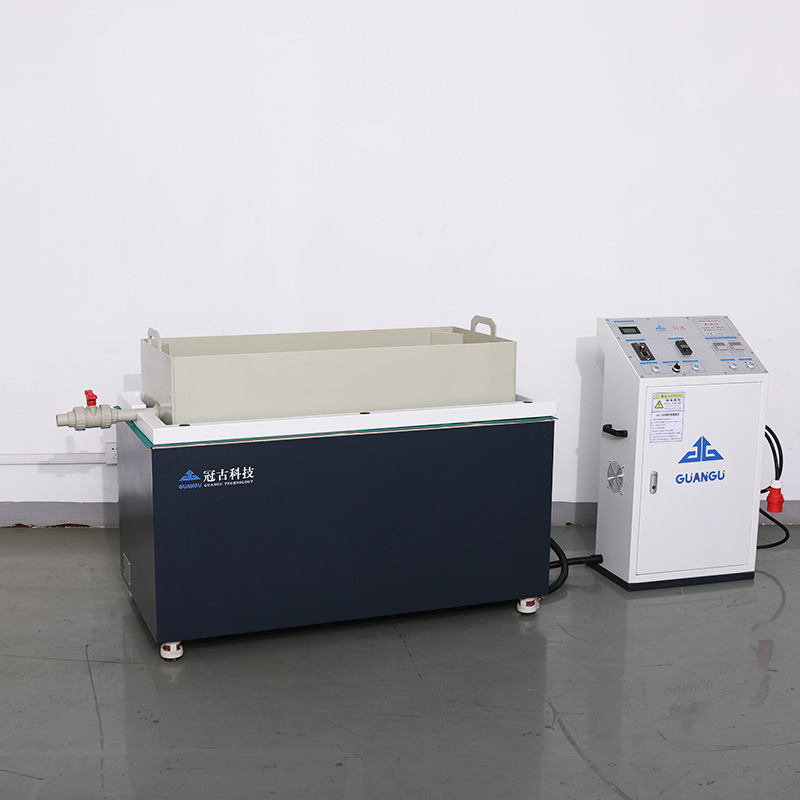

Dubrovnik-Large magnetic deburring machine

During the operation of a large magnetic deburring machine, metal workpieces do not collide with each other, and after magnetic grinding, the product does not deform, does not affect accuracy, and does not damage the surface of the workpiece;

Small magnetic deburring machine

« Previous post

13/04/2023

Wechat

Wechat